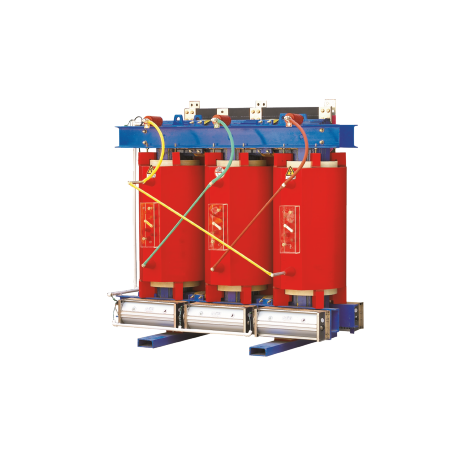

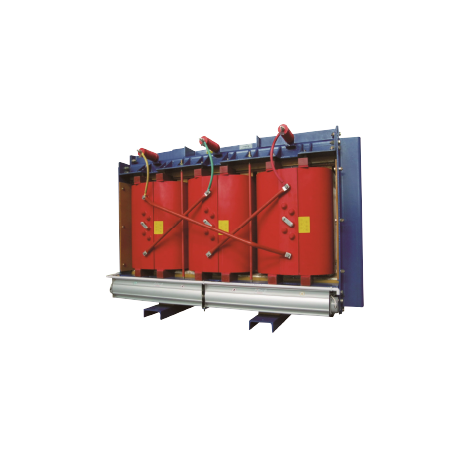

SC(B)10/11/12/13 10kV grade epoxy resin cast dry transformer

SUMMARY

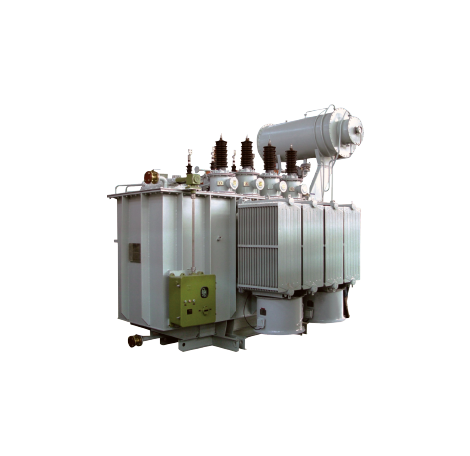

10kV grade SC(B)10, SC(B)11, SC(B)12, SC(B)13 epoxy resin cast dry-type transformers, can be used as an upgraded product of oil-immersed distribution transformers. The best performance of dry-type transformers is especially suitable for important places such as urban power grids, high-rise buildings, business centers, theaters, hospitals, hotels, tunnels, subways, stations, terminals, airports, underground power stations, laboratories, and combined substations.

DETAILS

Temperature control, temperature display

The temperature control system consists of a temperature controller and a PTC temperature measuring element installed at the hottest point of the product, that is, the upper end of the low voltage winding, to realize temperature measurement and control of the transformer. If the transformer winding temperature is too high due to overload operation or failure, the temperature controller An alarm signal is issued and the device trips itself when the temperature exceeds the safe value. When forced air cooling is used, the temperature controller determines the input or switching of the cooling fan according to the temperature of the winding.

The temperature display system directly displays the hot spot temperature of the winding during the operation of the transformer, and can be used together with the temperature control system.

The temperature control and temperature display system can be installed at a certain distance from the main body of the transformer. The lengths of the temperature measuring component leads are: temperature control: <20m; temperature display: <10m (two-wire system); <100m (with compensation wire Two-wire system).

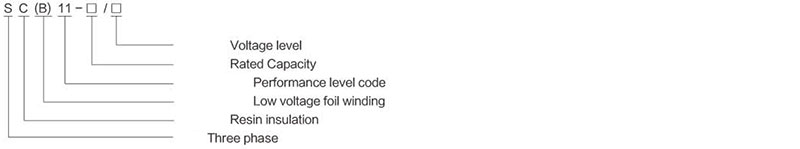

Model meaning

Features

The 10kV grade SC(B)10, SC(B)11, SC(B)12, SC(B)13 power transformers produced by our factory are the low noise and low loss type resin windings with the product model certificate earlier in China. Coil dry transformer. Thanks to advanced design, high-quality materials, scientific formula, strict process and high-standard testing, the products have the following characteristics:

● High-voltage winding copper wire, low-voltage winding with copper wire or copper foil, glass fiber felt filled and wrapped, vacuum-filled with epoxy resin without filler, solidified to form a solid cylindrical whole, mechanical strength High, partial discharge is small, and reliability is high.

● Flame retardant, explosion-proof and environmentally friendly. The insulating material such as glass fiber wound around the coil has self-extinguishing characteristics, and does not generate an arc due to a short circuit, and the resin does not generate toxic and harmful gas under high heat.

● The coil does not absorb moisture, and the core clip has a special anti-corrosion protection layer, which can operate in 100% relative humidity and other harsh environments. Intermittent operation does not require moisture treatment.

● High resistance to short circuit and lightning

● The inner and outer resin layers of the coil are thin and the heat dissipation performance is good. The cooling method is generally air-cooled (AN). For any degree of protection, the air cooling system (AF) can be configured to improve short-term overload capability and ensure safe operation.

● Low loss, good power saving effect, economical operation and maintenance-free.

● Small size, light weight, less floor space, low installation cost, no need to consider oil drain, fire protection facilities and backup power supply.

● Because there is no fire or explosion, it can be installed in the load center and close to the power consumption point, thus reducing the cost of the line and saving the cost of expensive low-voltage facilities.